CAPABILITIES

MACHINE SHOP CAPABILITIES

Tiros is housed in a 13,000 square foot, climate controlled facility. From prototype machining to large scale production, Tiros engages with customer purchasing, engineering, program management and quality assurance teams to ensure on-time delivery and 100% customer satisfaction.

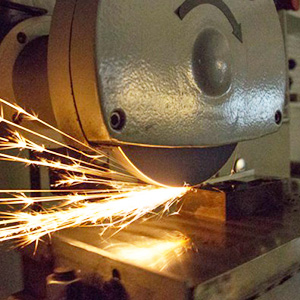

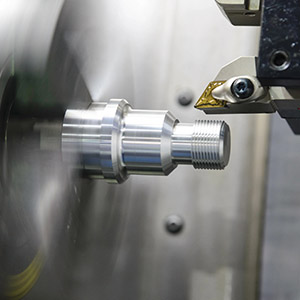

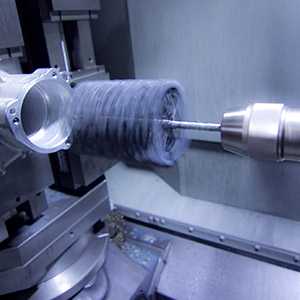

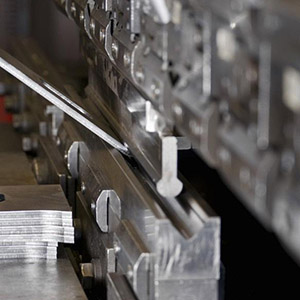

We are structured to offer a broad range of value-added services, providing standalone machined component parts to complete assemblies. Our operators routinely work with casting, forgings, alloys, stainless steel, bar stock, plastic, and other specialty materials. We manufacture within tolerances of +/- .0001 and have dedicated areas available for all inspection and assembly needs.

CNC Turning Centers

CNC Milling Machines

STRATEGIC PARTNERS & VENDORS

For outside processes, Tiros has established strategic partnerships with qualified subcontractors for heat treating, plating, welding, balancing, magnetic particle inspections and paint. Our long-standing relationships allow us to provide for all pre and post machining processes.